Dry goods sharing: Get to know high-temperature kiln equipment in one minute

Release time:

2023-01-07

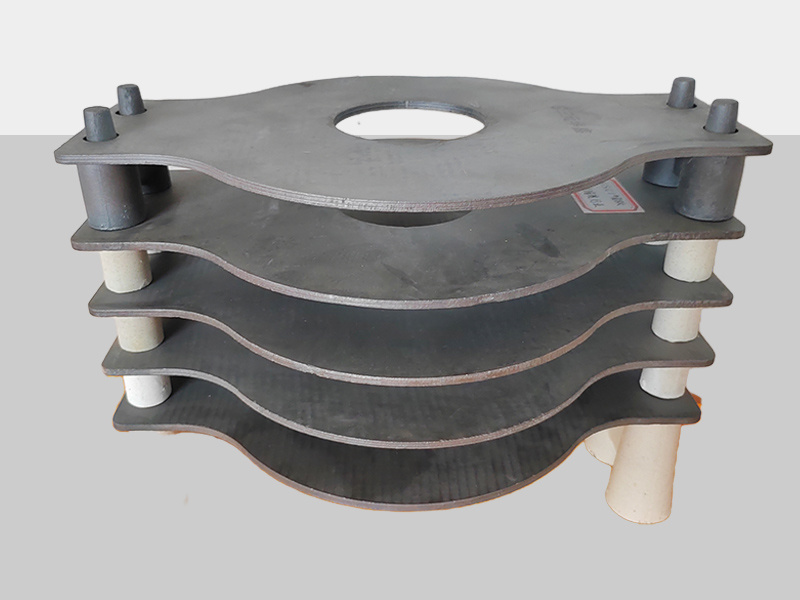

High-temperature Kiln Furniture That is, utensils made of refractory clay, which play a role in spacing, supporting, and protecting the green body during firing.

High-temperature kiln furniture was originally granular, also known as "bearing beads", and is made of white refractory clay and a large amount of alumina.

Due to the strong refractory nature of the spherical spacer kiln furniture, the phenomenon of collapse and adhesion has almost disappeared. Some spherical spacer kiln furniture with low requirements for different deformation influence levels may have been reused in China. In the later Eastern Han Dynasty, the celadon kilns in Shangyu District and other places all had three-legged cake-shaped intermittent kilns. These kilns were made of ordinary refractory clay, and the melting temperature was close to that of the porcelain body. Due to the high pressure on the contact surface between the three legs and the porcelain body, during the high-temperature firing stage, the tips of the legs fell into the porcelain body. After firing, the kiln furniture was knocked off, leaving three rough marks on the inside bottom of the bowl. The disadvantage of the three-legged cake-shaped spacer kiln furniture is that the weight cannot be too simply concentrated on the tips of the feet, which affects the quality of the product. Therefore, this type of kiln furniture was replaced by the toothed-mouth bowl-shaped spacer kiln furniture by the late Three Kingdoms period.

Toothed Mouth High-temperature Kiln Furniture It is also made of ordinary refractory clay, and the mouth is used facing downwards. Generally, it has more than six teeth, and the ends of the feet are rectangular. The working pressure on the contact surface with the porcelain body is much smaller than that of the previous three-legged cake-shaped spacer kiln furniture, which can effectively prevent the ends of the feet from sinking into the坯, improving product quality. At the same time, the ends of the kiln furniture are often coated with a little high-temperature white refractory clay, forming a toothed-mouth jar-shaped interval, which prevents the kiln furniture from sticking to the objects and facilitates the reuse of the kiln furniture. However, the weight of the toothed-mouth spoon-shaped spacer kiln furniture limits the number of stacking firings. Therefore, after the Eastern Jin Dynasty, Yue kilns no longer used this type of kiln furniture. Spherical spacer kiln furniture was generally used for stacking bowls and plates. The difference is that its volume became smaller, and the number of porcelain blanks used was four or more, rather than the three commonly used in the Spring and Autumn and Warring States periods. By the Tang and Five Dynasties period, the size of this spacer kiln furniture became smaller, and the shapes became more diverse, including spherical and strip shapes. Each porcelain blank often used more than a dozen pieces, scattered on clay balls or silver strips, and the weight was relatively lighter, so dozens of porcelain blanks could be stacked in each stack. The emergence and evolution of spacer kiln furniture all reflect the kiln workers' full development and utilization of kiln space. This behavior of pursuing product output under certain socio-temporal and economic conditions is governed by the natural law of conservation of energy.

The above is a brief introduction by the editor about High-temperature Kiln Furniture I hope it can help everyone.